TD75 type fixed belt conveyor

Technical characteristics and main parameters

The bulk density of the material can be transported by the conveyor in the range of 0.5-2.5T /m3.

This series conveyor is divided into: 500, 650, 800, 1000, 1200, 1400mm and other six specifications according to the bandwidth. The belt speed is 0.8m /s, 1.0m /s, 1.25m /s, 1.6m /s, 2.0m/s, 2.5m/s, 3.15m/s, 4.0m/s, etc. See the table on the following page for maximum throughput.

Driving device: the power range is 2.2~55Kw when the electric drum is used to drive, which can save space, but the ambient temperature should not exceed 40℃. When the power is greater than 55Kw, the motor, reducer and drum should be used to drive separately. The surface of the driving drum has three forms: bare steel surface, herringbone and rhombus rubber surface.

To the drum split surface and glue surface two.

Roller is made of seamless steel pipe, types: groove shape, flat shape, aligning, buffer four.

Tension device: Screw tensioning device is suitable for short length (< 100m), stroke of 500mm, 800mm, 1000mm three kinds; Vertical hammer tensioning device can automatically compensate the elongation of conveyor belt with the change of tension by gravity; Heavy hammer car type tensioning device is suitable for conveyors with long distance and large power. Its tensioning stroke is 2, 3 and 4M. Fixed winch tensioning device is used for belt conveyors with long distance and large tensioning force (30~150KN), long distance and large volume, and the maximum tensioning journey can reach 16m.

There are two kinds of head cleaner and empty segment cleaner.

Electrical protection can be provided with: conveyor belt deviation detector; Conveyor belt slip detector; Conveyor belt longitudinal tear signal detector; Material level control detector, etc.

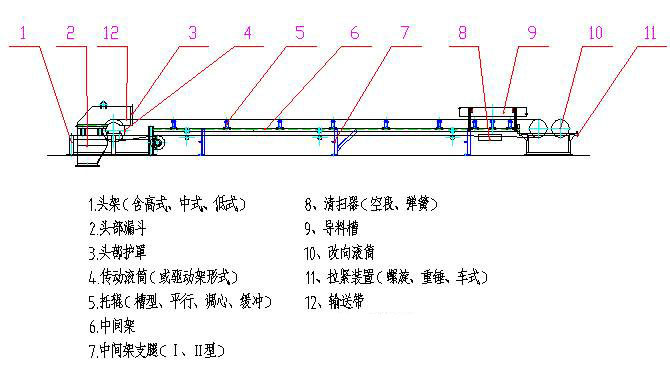

Structure diagram of TD75 belt conveyor

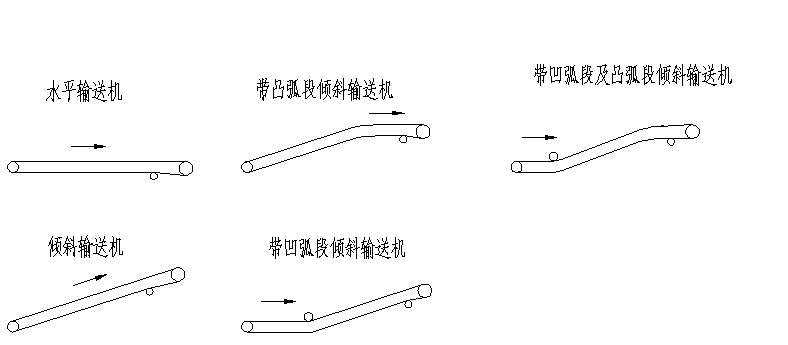

Basic layout of TD75 belt conveyor

Conveyor capacity of belt conveyor

| section

In the form of |

Tape speed

(m/s) |

Bandwidth B (mm) | |||||||||

| 500 | 650 | 800 | 1000 | 1200 | 1400 | ||||||

| Conveying capacity Q (t/h) | |||||||||||

| Trough type | 0.8

1.0 |

78

97 |

131

164 |

--

278 |

--

435 |

--

655 |

--

891 |

||||

| 1.25

1.6 2.0 2.5 3.15 4.0 |

122

156 191 232 -- -- |

206

264 323 391 -- -- |

348

445 546 661 824 -- |

544

696 853 1033 1233 -- |

819

1048 1284 1556 1858 2202 |

1115

1427 1748 2118 2528 2996 |

|||||

| flat | 0.8

1.0 1.25 1.6 2.0 2.5 |

41

52 66 84 103 125 |

67

88 110 142 174 211 |

118

147 184 236 289 350 |

--

230 288 368 451 546 |

--

345 432 553 677 821 |

--

469 588 753 922 1117 |

||||