NE/NES vertical conveyor bucket elevator

Structural features and working principle

NE, NSE series bucket elevator is composed of tail parts, head parts, bucket chain components, driving device components, fully closed casing, no material leakage when the equipment is running, lifting conveyor chain using punching plate chain, divided into single chain and double chain two types of arrangement, the head is set up with backstop, backstop reliable. The inlet and outlet of the equipment and the lifting height can be flexibly designed and arranged according to the technological requirements.

The material is uniformly introduced into the hopper fixed on the lifting chain for continuous closed operation through the inlet and outlet of the equipment, and the material is lifted from the inlet of the tail to the outlet of the nose to discharge, realizing single point of feed, single point of gravity type or mixed discharge.

The lifting conveyor chain adopts the hammer lever type automatic tensioning device to ensure that the lifting chain always maintains the appropriate tensioning device during operation, so that the equipment is in the best running state.

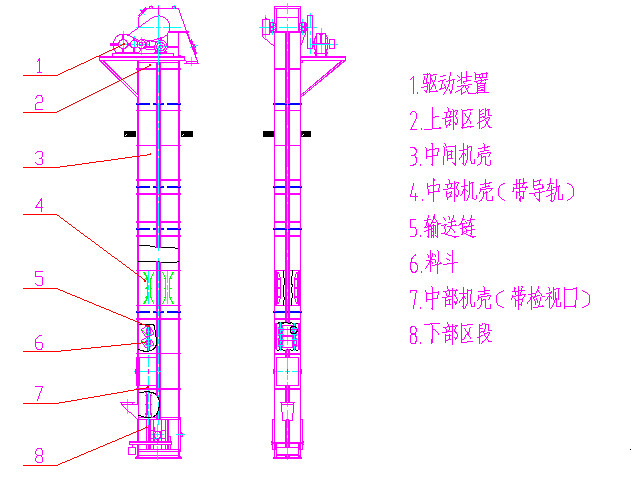

NE, NSE type bucket elevator structure diagram

NE type bucket elevator main technical parameters

| model | Throughput m3 / h | Bucket volume L | Bucket mm wide | The bucket from mm | Dou speed m/s | Spindle speed r/min | Maximum width of material mm |

| NE15 | 15 | 2.5 | 250 | 203.2 | 0.5 | 19.5 | -- |

| NE30 | 32 | 7.8 | 300 | 304.8 | 0.5 | 16.45 | 65 |

| NE50 | 60 | 14.7 | 300 | 304.8 | 0.5 | 16.45 | 65 |

| NE100 | 110 | 35 | 400 | 400 | 0.5 | 14.13 | 95 |

| NE150 | 170 | 52.2 | 600 | 400 | 0.5 | 14.13 | 95 |

| NE200 | 210 | 84.6 | 600 | 500 | 0.5 | 10.9 | 125 |

| NE300 | 320 | 127.5 | 600 | 500 | 0.5 | 10.9 | 125 |

| NE400 | 380 | 182.6 | 700 | 600 | 0.5 | 8.3 | 145 |

| NE500 | 470 | 260.9 | 700 | 700 | 0.5 | 7.1 | 165 |

| NE600 | 600 | 300.2 | 700 | 700 | 0.5 | 7.1 | 165 |

| NE800 | 800 | 501.3 | 800 | 800 | 0.5 | 7.1 | 195 |