HD type bag filter

Description

I. Overview:

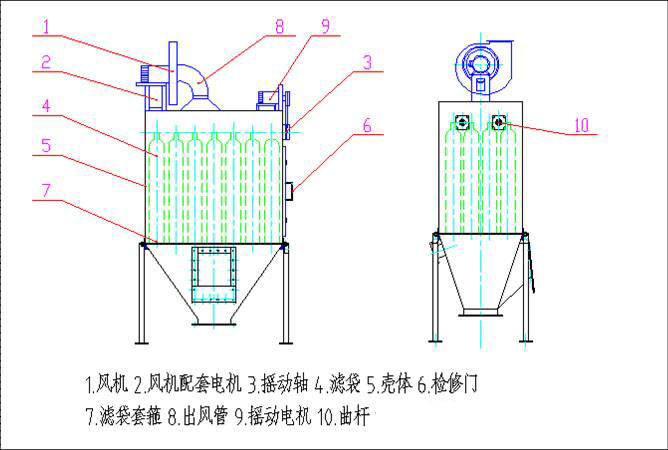

HD series single dust collector is specially designed for cement top storage, storage bottom, belt transport and local dust source dust removal. It can also be used for local dust source dust removal in other industries. It has the advantages of small volume, large processing air volume, compact structure, convenient and reliable use. The dust removed from the dust collector can be directly discharged into the warehouse or directly landed on the belt. Dust-containing gas enters the dust collector from the lower part of the dust collector and is filtered by the filter bag, and the clean air is discharged by the induced draft fan. After the dust collector works for a period of time, the dust on the filter bag gradually increases, which causes the resistance of the filter bag to rise. It is necessary to clean the dust.

Two, working principle:

The dust-containing gas enters the chamber through the inlet of the dust collector and is filtered through the filter bag. The dust is left on the inner surface of the filter bag. The purified gas enters the fan through the filter bag, is inhaled by the fan, and is directly discharged into the room (or can be taken over and discharged to the outdoor). With the increase of filtering time, inner surface adhesion of dust filter bag is also increasing, filter bag resistance increases, thus influence dedusting effect, using self-control soot cleaning to swing soot cleaning regularly or manual ash removal device, automatic swing tens of seconds after downtime, make with shake down on the surface of the filter bag, dust, dust fall to ash hopper, drawer or falls directly on the conveyor belt.

Three, the scope of use:

This series of products are widely used in cement industry, but also for casting industry, ceramic industry, glass industry, grinding wheel manufacturing, chemical products, mechanical processing and other industries of dust removal. The product has good dust removal effect on metal chips with large proportion, foundry sand and dust with medium proportion, such as cement, ceramics, gypsum powder, asbestos powder, carbon powder, pigment, bakerwood powder, plastic powder, and wood processing dust with light proportion, and the emission concentration is guaranteed to meet the national emission requirements.

2PGC double tooth roller crusher structure diagram

Technical parameter table

| Technical Performance Model | HD24(A、B、C) | HD32(A、B、C) | HD48(A、B、C) | HD56(A、B、C) | HD64(A、B、C) | HD64L(A、B、C) | HD80(A、B、C) |

| Filtration area /m2 | 10 | 15 | 20 | 25 | 29 | 35 | 40 |

| Filter bag quantity/each | 24 | 32 | 48 | 56 | 64 | 64 | 80 |

| Filter specifications(Ф * L)/mm | Ф115×1270 | Ф115×1270 | Ф115×1270 | Ф115×1270 | Ф115×1270 | Ф115×1535 | Ф115×1535 |

| Handle air volume /(m3 / h) | 824~1209 | 1401~1978 | 2269~2817 | 2198~3297 | 3572~3847 | 3912~5477 | 3912~5477 |

| Equipment resistance /Pa | <1200 | <1200 | <1200 | <1200 | <1200 | <1200 | <1200 |

| Dust removal efficiency /% | >99.5 | >99.5 | >99.5 | >99.5 | >99.5 | >99.5 | >99.5 |

| Filter air speed /(m/min) | <2.5 | <2.5 | <2.5 | <2.5 | <2.5 | <2.5 | <2.5 |

| Fan power/kW | 2.2 | 3 | 5.5 | 5.5 | 7.5 | 11 | 11 |

| Dust cleaning motor power/kW | 0.25 | 0.25 | 0.25 | 0.37 | 0.37 | 0. 37 | 0.55 |

| Type of fan motor | Y90L-2 | Y100L-2 | Y132S1-2 | Y132SL-2 | Y132S2-2 | Y160M1L-2 | Y160M1-2 |

| Model of dust cleaning motor | AO2-7114 | AO2-7114 | AO2-7114 | AO2-7114 | AO2-7114 | AO2-7114 | AO2-7114 |